The $2.5 Trillion Question: How PE is Rewiring Global Supply Chains

Aug 06, 2025

Private equity's strategic pivot from cost optimization to resilience engineering is reshaping competitive advantage across portfolio companies

The conventional wisdom that guided global supply chains for decades—optimize relentlessly for cost and efficiency—lies in ruins. COVID-19 exposed the fragility of just-in-time systems. The Russia-Ukraine conflict revealed the vulnerabilities of single-source dependencies. China's lockdowns demonstrated the risks of geographic concentration. What emerged from this cascade of disruptions wasn't just operational chaos, but a fundamental reckoning with the architecture of global commerce itself.

Private equity firms, with their characteristic ability to identify and capitalize on structural shifts, recognized this inflection point earlier than most. The traditional PE playbook of financial engineering and cost reduction has evolved into something more sophisticated: supply chain value engineering. Across their portfolios, PE firms are deploying unprecedented capital and operational expertise to build supply chains that prioritize resilience without sacrificing efficiency, localization without abandoning scale advantages, and sustainability without compromising profitability.

The Great Recalibration

The shift represents more than tactical adjustments—it's a wholesale reimagining of how value is created through supply chain orchestration. For decades, the pursuit of comparative advantage drove manufacturing and sourcing to the cheapest global locations. Complex, interconnected networks spanning continents became the norm, optimized for cost and underpinned by the assumption that disruptions would be rare and manageable.

This model delivered extraordinary efficiency gains and profit margins, but it also created systemic vulnerabilities that recent events brutally exposed. The semiconductor shortage that crippled automotive production. The Suez Canal blockage that paralyzed global trade. The cascading effects of factory shutdowns in China that rippled through electronics supply chains worldwide. Each crisis reinforced the same uncomfortable truth: the most efficient system is often the most fragile.

The New PE Value Creation Playbook

Due Diligence Revolution

Supply chain analysis has migrated from the periphery to the center of PE due diligence processes. Deal teams now conduct exhaustive mapping of supplier ecosystems, identifying single points of failure with the same rigor they once reserved for financial statement analysis. Geopolitical risk assessment has become standard practice, with firms evaluating everything from trade route dependencies to regulatory exposure across jurisdictions.

The focus extends beyond immediate suppliers to encompass entire networks—the suppliers' suppliers, critical raw material sources, and transportation chokepoints. This granular understanding enables PE firms to accurately price supply chain risks and identify opportunities for value creation through strategic interventions.

Technology-First Transformation

The digitalization of supply chains has emerged as a primary investment thesis across PE portfolios. Artificial intelligence and machine learning algorithms are being deployed to transform demand forecasting from educated guesswork into predictive science. These systems analyze vast datasets—historical sales patterns, market trends, weather data, even social media sentiment—to generate demand forecasts with unprecedented accuracy.

Simultaneously, blockchain and IoT technologies are creating end-to-end transparency that was previously impossible. Every component can be tracked from origin to final assembly, every transaction recorded immutably, every environmental condition monitored in real-time. This transparency enables not just better operational decisions but also compliance with increasingly stringent ESG requirements and consumer demands for ethical sourcing.

The Localization Imperative

Perhaps no trend better illustrates the supply chain transformation than the accelerating shift toward nearshoring and reshoring. PE-backed companies are systematically relocating production capabilities closer to end markets, driven by a recognition that proximity offers strategic advantages beyond risk mitigation.

The automotive sector exemplifies this transformation. Component suppliers that once concentrated production in distant locations are establishing regional manufacturing hubs to serve major assembly plants. The initial cost premium is offset by reduced logistics expenses, faster response times, and elimination of inventory buffers needed to manage long-distance supply chains.

Sectoral Applications

The localization imperative varies significantly across industries. In pharmaceuticals and defense—sectors where supply security is paramount—PE firms are facilitating wholesale reshoring initiatives, often with government support. The food and agriculture sectors are emphasizing local sourcing to meet consumer demands for freshness and reduced environmental impact while enhancing supply security.

Electronics manufacturing presents a more complex challenge, given the industry's deep integration with Asian supply chains. Here, PE firms are pursuing hybrid strategies—maintaining Asian production for cost-sensitive components while establishing regional assembly and testing capabilities to reduce lead times and enhance responsiveness.

Building Antifragile Supply Chains

The ultimate goal isn't simply resilience—the ability to bounce back from disruptions. It's antifragility—the capacity to emerge stronger from shocks. PE firms are systematically building this capability through multi-dimensional strategies that address supplier relationships, inventory management, and organizational preparedness.

Supplier Ecosystem Engineering

The single-supplier model that dominated cost-optimization strategies is being replaced by carefully orchestrated multi-source networks. This isn't simply about having backup suppliers—it's about creating competitive dynamics that drive innovation while ensuring supply security. PE firms are implementing sophisticated supplier financial health monitoring systems, recognizing that a supplier's bankruptcy can quickly become their portfolio company's crisis.

Geographic diversification extends beyond simple risk mitigation. By spreading supplier relationships across multiple regions, PE-backed companies can capitalize on regional cost advantages while maintaining supply continuity. When disruptions occur in one region, production can shift seamlessly to alternative sources without operational interruption.

Strategic Inventory Positioning

The lean inventory principles that drove just-in-time systems are being recalibrated rather than abandoned. The new approach recognizes that different components require different inventory strategies based on their criticality, supply risk, and demand volatility. AI-powered systems optimize safety stock levels continuously, balancing carrying costs against disruption risks with sophisticated mathematical models.

The ESG Integration Imperative

Supply chain transformation in the PE context cannot be separated from ESG considerations. Environmental compliance, social responsibility, and governance standards have evolved from nice-to-have attributes to value-critical requirements that directly impact enterprise valuation and exit potential.

Carbon footprint reduction through supply chain optimization delivers dual benefits—regulatory compliance and operational efficiency. Shorter supply chains inherently generate lower emissions, while advanced analytics optimize transportation routes and modes to minimize environmental impact without sacrificing service levels.

Labor practices throughout supplier networks now face unprecedented scrutiny. PE firms are implementing comprehensive supplier audit programs, not just for risk mitigation but for positive value creation through enhanced brand reputation and customer loyalty.

Value Creation Through Operational Excellence

The financial returns from supply chain transformation extend far beyond cost savings. Enhanced resilience reduces the probability and impact of operational disruptions that can destroy enterprise value. Improved responsiveness enables companies to capitalize on market opportunities more quickly than competitors. Superior ESG performance attracts both customers and acquirers willing to pay premium multiples.

The technology investments driving supply chain transformation also create valuable intellectual property and operational capabilities that differentiate portfolio companies in their markets. Advanced analytics capabilities, proprietary supplier networks, and optimized production processes become sustainable sources of competitive advantage that persist well beyond the PE holding period.

The Strategic Imperative

The supply chain transformation unfolding across PE portfolios represents more than operational optimization—it's a fundamental reimagining of how value is created in the global economy. The firms that recognize this shift early and invest accordingly will build sustainable competitive advantages that compound over time.

The old paradigm of purely cost-driven supply chains is not merely outdated—it's competitively dangerous. In a world characterized by increasing volatility and stakeholder expectations for transparency and responsibility, the companies that excel will be those that have built supply chains capable of adapting, evolving, and thriving under pressure.

Private equity's role in this transformation extends beyond capital deployment to strategic orchestration of fundamental business model evolution. The $2.5 trillion question isn't whether this transformation will continue—it's which firms will lead it and which will be left behind by it.

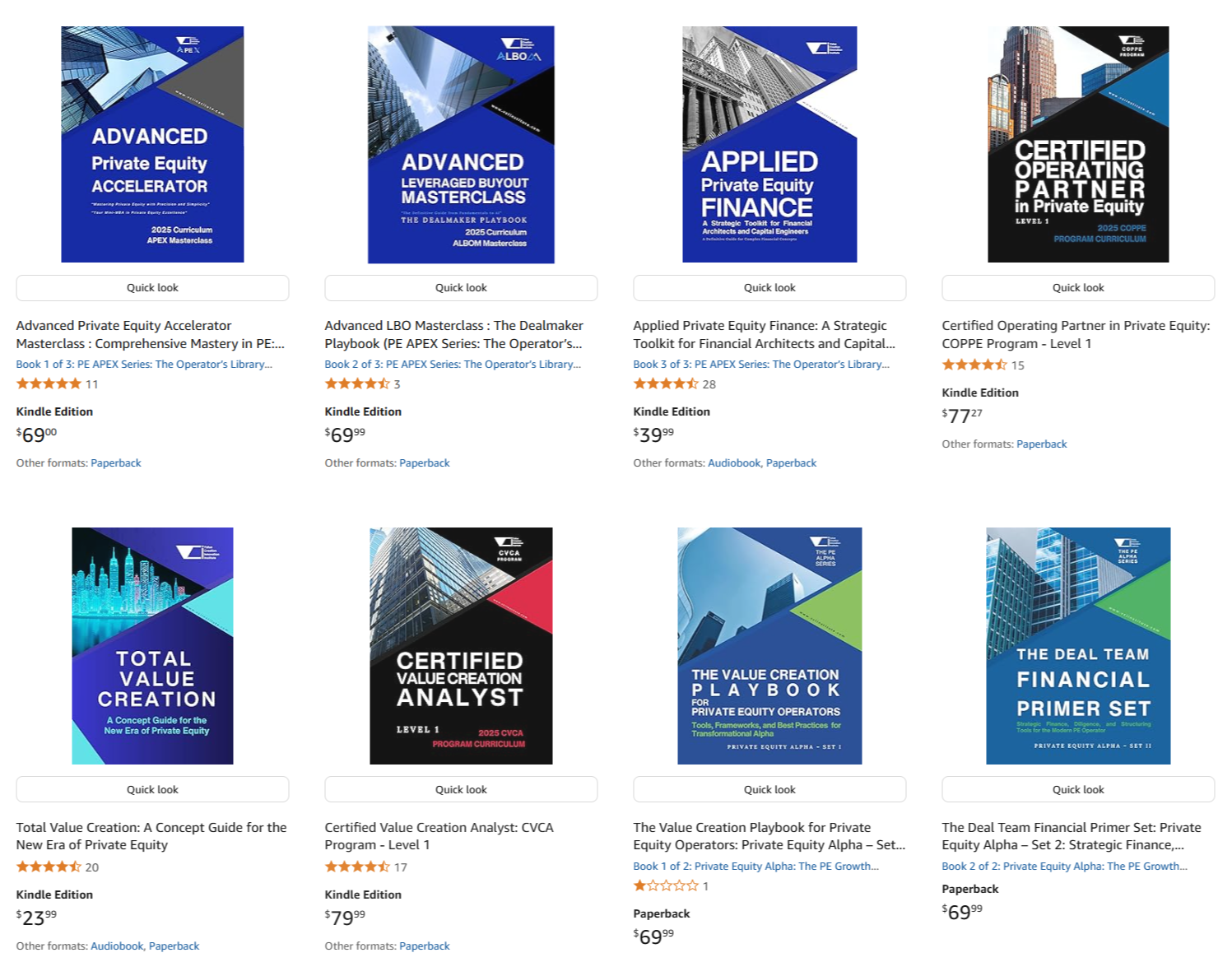

We have many great affordable courses waiting for you!

Stay connected with news and updates!

Join our mailing list to receive the latest news and updates from our team.

Don't worry, your information will not be shared.

We hate SPAM. We will never sell your information, for any reason.